Capabilities

Engineering Services

Space Vector maintains in-house all the capability necessary to take a program or project from concept to production. Our engineering and manufacturing organizations have the necessary experience and creativity to provide innovative solutions to the most complex tasks.

Our cohesive team consists of experts in the fields of:

- Systems Engineering

- Electrical Engineering/Avionics

- Mechanical Engineering/Propulsion & Structures

- Software Design

- Simulation/Modeling/Flight Analysis

- Production Control

- Program Management

Design & Analysis

Space Vector has over 40 years of experience in launch vehicle design and missile guidance and control (G&C).

Control System Analysis and Design

- Design - Given a vehicle system to control we can develop a model and feedback control system to optimize performance based on design goals.

- Implementation - Using the most modern tools we can implement the control electronics using hardware (CPLD, FPGM) or software (mP, DSP) implementations based on design goals.

- Independent Review - Space Vector can provide an independent review of an existing or proposed control system design including a comprehensive report identifying strengths and weaknesses of the design along with suggestions for improvement.

Mission Analysis and Planning

- A comprehensive database of booster and vehicle performance parameters

- 6 DOF trajectory simulation tools that include vehicle bending modes

- Wind loading profiles and Monte Carlo dispersion predictions

- Visualization aids like STK and Truespace

- Trajectory shaping to optimize mission parameters (i.e. look times, line of sight, etc.)

- Multibody and complex geometry engagement analysis techniques

- Aerodynamic predictions (Missile Datcom, AP98, CFD)

- Load Development and Environmental Predictions

Vehicle Design

- 3D Solid Modeling (SolidWorks)

- Finite Element Analysis (FEA)

- Thermal Analysis and Protection Systems

- Mass Properties Generation

Electrical System Development

- Electrical Interfaces and Cabling

- Thrust Vector Control Interface Simulation

- Ordnance Safe and Arm Design

- Transmitter Sizing

- Antenna Selection

- Signal Conditioning

- Power Distribution and Switching

- Communications

- Ground Terminals

- Vehicle and Payload Subsystems

- Attitude Control System Thruster Interface

- Separation Ordnance Control

Software Development

- Embedded Flight Code Generation

- Mission Timeline Implementation

- Software V&V with HWIL

Avionics

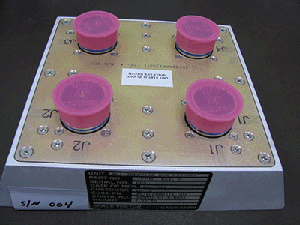

Space Vector produces a variety of custom avionics boxes for the launch vehicle industry. Some boxes are build-to-print to customer designs but most are designed-to-specification where Space Vector provides all the engineering design and documentation. We also perform all the necessary individual acceptance testing (IAT) on each unit and qualification testing required by the program.

Examples of custom avionics developed by Space Vector include:

- Power Distribution Units (PDU)

- Payload Sequencers and Switching Units

- Thrust Vector Control Junction Boxes and Controllers

- Vehicle Interface Units (AKA Missile Interface Units)

- Flight Termination System Relay Boxes

- Telemetry Signal Conditioners

Test & Integration

Element and System Tests

- Component and Subsystem Acceptance and Qualification Testing

- Vehicle Assembly at SVC

- End-to-End System Testing

- Hardware-in-the-loop

- Mission Timeline

- Booster and Ordnance Simulators

- Post Boost Air Bearing Testing as required

- EMI/EMC Testing with Range Asset

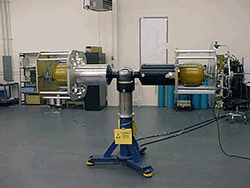

ait-2 Payload Modal Analysis

Payload Integration

- Mechanical and Electrical ICD Development

- Payload and Vehicle Telemetry

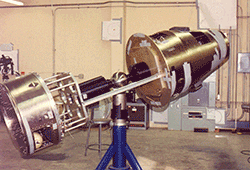

Air Bearing Testing

The Space Vector air bearing facility is used to to test post boost attitude control systems in a space-like environment. This is a complete hardware-in-the-loop (HWIL) test running the flight software. TM data and laser pointer traces are used to verify system performance.

Dual Payload Airbearing Test Single Payload Airbearing Test

Special Test Equipment

Space Vector has developed a variety of ruggedized test consoles using proven data acquisition and analysis software together with data acquisition cards. The test consoles are centered around a COTS computer. Standard models are designed into a two to three stack 19-inch rack anti-vibration transit cases with an optional printer.

One of our key pieces of test equipment is the Telemetry Ground Station. This system can receive up to 5 S-Band PCM links (2200 to 2400 MHz) simultaneously. Each link has a 10 Mbit/sec data width and outputs can be configured as NRZL, NRZM, NRZS, and 422 data. The system uses dual processors operating at 450 MHz. Data is stored directly to an 18 GB hard drive for processing.

GPS Simulation

Space Vector owns two GPS constellation simulators: A Spirent GSS7700 and a dual output GSS8000. These simulators are used for testing our GPS tracking units under flight representative scenarios.